What materials are used for tyres: synthetic rubber, natural rubber, fabric and wire, along with carbon black and other chemical compounds, make tyres. They consist of a tread and a body.

What is the tyre tread : the tread is the part of the tyre that comes in contact with the road surface. The portion that is in contact with the road at a given instant in time is the contact patch. The tread is a thick rubber, or rubber/composite compound formulated to provide an appropriate level of traction that does not wear away too quickly.

The tread pattern is characterized by a system of circumferential grooves, lateral sipes, and slots for road tyres or a system of lugs and voids for tyres designed for soft terrain or snow. Grooves run circumferentially around the tyre, and are needed to channel away water. Lugs are that portion of the tread design that contacts the road surface. Grooves, sipes and slots allow tyres to evacuate water.

The design of treads and the interaction of specific tyre types with the roadway surface affects roadway noise, a source of noise pollution emanating from moving vehicles. These sound intensities increase with higher vehicle speeds. Tyres treads may incorporate a variety of distances between slots (pitch lengths) to minimize noise levels at discrete frequencies. Sipes are slits cut across the tyre, usually perpendicular to the grooves, which allow the water from the grooves to escape sideways and mitigate hydroplaning.

Different tread designs address a variety of driving conditions. As the ratio of tyre tread area to groove area increases, so does tyre friction on dry pavement, as seen on Formula One tyres, some of which have no grooves. High-performance tyres often have smaller void areas to provide more rubber in contact with the road for higher traction, but may be compounded with softer rubber that provides better traction, but wears quickly. Mud and snow (M&S) tyres employ larger and deeper slots to engage mud and snow. Snow tyres have still larger and deeper slots that compact snow and create shear strength within the compacted snow to improve braking and cornering performance.

Wear bars (or wear indicators) are raised features located at the bottom of the tread grooves that indicate the tyre has reached its wear limit. When the tread lugs are worn to the point that the wear bars connect across the lugs, the tyres are fully worn and should be taken out of service, typically at a remaining tread depth of 1.6 millimeters (0.063 in).

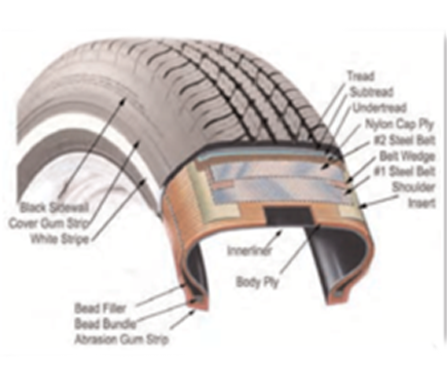

What is the tyre bead : the tyre bead is the part of the tyre that contacts the rim on the wheel. The bead is typically reinforced with steel wire and compounded of high strength, low flexibility rubber. The bead seats tightly against the two rims on the wheel to ensure that a tubeless tyre holds air without leakage. The bead fit is tight to ensure the tyre does not shift circumferentially as the wheel rotates.

What is the tyre sidewall : the sidewall bridges between the tread and bead. The sidewall is largely rubber but reinforced with fabric or steel cords that provide for tensile strength and flexibility. The sidewall contains air pressure and transmits the torque applied by the drive axle to the tread to create traction but supports little of the weight of the vehicle, as is clear from the total collapse of the tyre when punctured. Sidewalls are molded with manufacturer-specific detail, government mandated warning labels, and other consumer information.

What kind of design is used for car tyres: in automotive the tyres used the radial design. In a radial tyre the cord plies of the fabric are arranged at 90 degrees to the direction of travel, or radially (from the center of the tyre). This design avoids having the plies rub against each other as the tyre flexes, reducing the tyre's rolling friction.

What is the carcass: a series of plies of cord reinforces a tyre and the network of cords that gives the tyre strength and shape is called the carcass. With only radial cords, a radial tyre would not be sufficiently rigid at the contact with the ground. To add further stiffness, the entyre tyre is surrounded by additional belts oriented closer to the direction of travel, but usually at some "spiral" angle. These belts can be made of steel (hence the term steel-belted radial), polyester, or Aramid fibers such as Twaron or Kevlar.

Light-duty tyres for passenger vehicles carry loads in the range of 550 to 1,100 pounds (250 to 500 kg) on the drive wheel. Light-to-medium duty trucks and vans carry loads in the range of 1,100 to 3,300 pounds (500 to 1,500 kg) on the drive wheel. They are differentiated by speed rating for different vehicles, including (starting from the lowest speed to the highest: winter tyres, light truck tyres, entry-level car tyres, sedans and vans, sport sedans, and high-performance cars.

Snow tyres are designed for use on snow and ice. They have a tread design with larger gaps than those on summer tyres, increasing traction on snow and ice. Such tyres that have passed a specific winter traction performance test are entitled to display a "Three-Peak Mountain Snow Flake" symbol on their sidewalls. Tyres designed for winter conditions are optimized to drive at temperatures below 7 °C (45 °F). Some snow tyres have metal or ceramic studs that protrude from the tyre to increase traction on hard-packed snow or ice. Studs abrade dry pavement, causing dust and creating wear in the wheel path.[24] Regulations that require the use of snow tyres or permit the use of studs vary by country in Asia and Europe, and by state or province in North America.

All-season tyres are typically rated for mud and snow (M+S). These tyres have tread gaps that are smaller than snow tyres and larger than conventional tyres.

All-terrain tyres are designed to have adequate traction off-road, yet have benign handling and noise characteristics for highway driving. Such tyres are rated better on snow and rain than street tyres and "good" on ice, rock and sand.

Mud-terrain tyres have a deeper, more open tread for good grip in mud, than all-terrain tyres, but perform less well on pavement.

High-performance tyres are rated for speeds up to 168 miles per hour (270 km/h) and ultra-high-performance tyres are rated for speeds up to 186 miles per hour (299 km/h), but have harsher ride characteristics and durability.]

Run-flat tyres obviate the need for a spare tyre, because they can be traveled on at a reduced speed in the event of a puncture, using a stiff sidewall to prevent damage to the tyre rim.

Race car tyres come in three main categories, DOT (street-legal) semislick, slick, and rain. Race car tyres are designed to maximize cornering and acceleration friction at the expense of longevity. Racing slicks have no tread to maximize contact with the pavement and rain tyres have channels to eject water to avoid hydroplaning.

Source:

https://en.wikipedia.org/wiki/Tyre

https://en.wikipedia.org/wiki/Radial_tyre

edited by arrabbiata